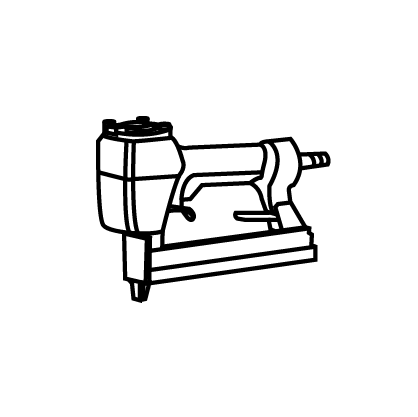

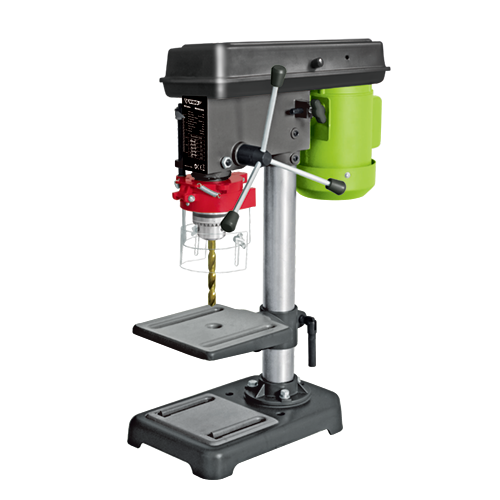

Operation rules of drilling machine.

1、Before working, you must check if the operating mechanism of each department is normal, wipe the rocker arm guide with fine cotton yarn and fill it with oil according to the lubricant grade.

2. The rocker arm and spindle box should be locked before operation.

3. No obstacle is allowed within the swinging range of the rocker arm.

4、Before starting drilling, the table, workpiece, fixture and cutting tool of the drilling machine must be corrected and fastened.

5. Correctly select the spindle speed and tool feed, and do not overload the machine.

6. The workpiece must be smoothly drilled beyond the table.

7. When the machine tool is running and automatically feeds the tool, it is not allowed to change the fastening speed, and if the speed is changed, it can only be done when the spindle stops completely.

8. Loading and unloading of cutting tools and measuring workpieces must be carried out in the stop, not allowed to directly hold the workpiece drilling, not to wear gloves.

9. If any abnormal noise is detected during the work, the machine must be stopped immediately for troubleshooting.

Drilling machine inspection items.

1. The flatness of the base table.

2. Flatness of the working table.

3. Table runout.

4. Radial runout of spindle taper hole axis.5. Radial runout of spindle rotation axis.

6. Perpendicularity of the spindle rotation axis to the working surface of the base.

7. Vertical movement of the spindle sleeve to the verticality of the working surface of the base.

8. The change of spindle axis to table verticality under the action of spindle axial force.

1.Wide range of materials that can be processed

CNC drilling center can process many kinds of materials because the equipment can change different tools at will. Whether it is steel or aluminum alloy and copper aluminum stainless steel and other hardware materials can be processed. Some materials with high hardness can also be processed on the CNC drilling machine as long as the corresponding tools are changed. Thus, it can be seen that the CNC drilling center is favored by users from all walks of life, which is inseparable from its advantages in processing. In addition, the famous CNC drilling and tapping center also has the advantages of stable operation and advanced technology. With the mutual help of the major advantages, the continuous development of CNC drilling and processing workpiece drilling is promoted.

2. Can meet the requirements of high-volume processing

CNC drilling and tapping center adopts multi-axis, multi-tool, multi-sequence or multi-surface processing method. By drilling and tapping, multiple processes can be operated at one time, which can meet the needs of a large number of enterprises or mass production. The CNC drilling center is equivalent to a complete set of automatic production line, which can quickly complete the processing and production of many different processes.

3. High processing accuracy and small error

CNC drilling and tapping center adopts intelligent system control, which can design and control various processing specifications. Either extracting teeth or pulling teeth can achieve accurate slotting processing. Therefore, you can also choose CNC drilling machine to complete the design and processing of workpieces with strict processing requirements.

Maintenance of the drilling machine.

1. Drilling machine should have operating procedures: regular maintenance, maintenance, failure to pay attention to the record to protect the site, etc.2. Power requirements

3. The drilling machine should be kept in oil seal when not in use and covered with sealing film outside

4. Training and equipping the corresponding operators, maintenance personnel and programming personnel

Cleaning of the drilling machine.

1.Wipe the drilling table, bed, guide, screw and operating handle. Keep the bed and the surrounding area clean and free of oil.2. remove the burrs on the guideway surface and impurities from the drill slag of the screw.

3. disassemble and clean the linoleum.

4. Remove rust from all parts of the drilling machine and protect the painted surface.