Components of the air compressor

1. Oil circulation system

Before starting, first start the oil pump control system, the oil pump control system starts to ensure that all lubrication parts of the air compressor are well lubricated, while the oil pump control system can adjust the internal oil pressure and oil temperature through the built-in temperature control valve to meet the needs of the system.

2. Air circuit circulation system

When the compressor works, the air is sucked in through the self-cleaning air filter, and the filter is cleaned automatically through PLC, and the air enters the primary compression after the automatic adjustment of the inlet guide vane, and the gas temperature is higher after the primary compression, and then enters the intercooler for cooling (water goes inside the pipe, gas goes outside the pipe, and the water flow rate of the intercooler is required to be 110m/h) and then enters the secondary compression system afterwards, in order to avoid the system gas back into the compression chamber (to avoid starting with pressure) in the compressor exhaust pipeline is installed with a suspended full-opening check valve, the gas discharged from the compressor push open the check valve into the exhaust muffler, and then into the first after-cooler, second after-cooler, and then into the exhaust main pipeline.

3. Water circulation system

The cooling water enters the intercooler of the compressor through the pipeline to cool the gas discharged from the primary compression, and then enters the after-cooler to cool the exhaust, and the other cooling water inlet pipeline passes through the two groups of heat exchangers on the upper part of the main motor to cool the motor windings, and there is another way to cool the oil cooler.

4. Power distribution system

The air compressor is a 2000kW high-voltage motor (10kV) with full-voltage start. The control cabinet is an indoor AC, metal-clad withdrawable switchgear, which consists of two major parts: fixed cabinet and withdrawable parts, i.e. trolley, to realize the purpose of control, protection and monitoring, with "five-proof" function.

5. Screen protection system

The central signal device is divided into two kinds of accident signals and advance signals. The main task of the accident signal is in the circuit breaker accident tripping, can timely sound signal, and make the corresponding circuit breaker light position signal flash. The main task of the forewarning signal is in the event of abnormalities in the operating equipment, instantaneous or delayed sound signal, and make the light sign shows the content of the abnormalities.

6. DC power supply system

PZ32 series automatic maintenance-free lead-acid battery DC power supply set is composed of charging device screen, DC feeder screen and battery, with automatic current stabilization, automatic voltage stabilization, automatic voltage regulation and other functions, providing power for the central signal screen and high-voltage control system.

7.DTC control system

The DTC control panel is the "brain" of the air compressor. The values of various field sensors are finally summed up to the DTC control panel, which displays various operating parameters on the DTC control panel and monitors the operating status of various parts of the air compressor.

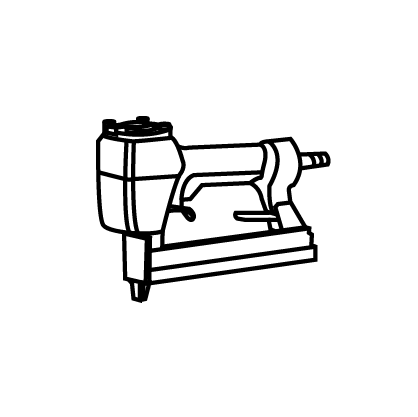

air-compressor

Uses of air compressor

1. traditional air power: wind tools, rock drills, air picks, pneumatic wrenches, pneumatic sandblasting.

2. Instrumentation control and automation devices, such as tool change in machining centers, etc.

3. Vehicle braking, door and window opening and closing.

4. Air-jet loom with compressed air blowing weft yarn to replace the shuttle.

5. Food, pharmaceutical industry, the use of compressed air to stir the slurry.

6. Large marine diesel engine starting.

7. Wind tunnel experiments, underground tunnel air exchange, metal smelting.

8. Oil well fracturing

9.High pressure air blasting coal mining.

10. Weapon system, missile launch, torpedo launch.

11. Submarine floating, wreck salvage, submarine oil exploration, hovercraft.

12. Tire inflation.

13.Paint spraying.

14.Bottle blowing machine.

15.Air separation industry.16.Industrial control power (drive cylinders, pneumatic components).

17.Production of high pressure air for cooling and drying of machined parts.

VIDO is a professional tool manufacturer, producing a wide range of tools, including chainsaws, vacuum cleaners, air compressors and so on. We have a wide variety of products and export overseas, which have been well received by everyone. If you are interested in professional tools, you can contact our company.