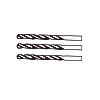

As a tool that is more commonly used in daily life, do you know some basic information about it? Drill bits often have various problems in daily life, so how should we deal with them?

Reasons for drill tip wear

1. The workpiece will move downward under the force of drilling into the drill bit, and the drill bit will spring back after drilling through.2. Insufficient rigidity of the machine tool.

3. The drill bit material is not strong enough.

4. The runout of the drill bit is too large.

5. Insufficient clamping rigidity, the drill bit slips.

Countermeasures for drill tip wear

1. Reduce the cutting speed.

2. Increase the feed amount.

3. Adjust the cooling direction (internal cooling).

4. Add a chamfer.

5. Check and adjust the coaxiality of the drill bit.

6. Check whether the back angle is reasonable.

Reasons for drill ligament chipping

1. The workpiece will move downward under the force of drilling into the drill bit, and the drill bit will spring back after drilling through.

2. Insufficient rigidity of the machine tool.

3. The drill bit material is not strong enough.

4. The runout of the drill bit is too large.

5. Not enough clamping rigidity, the drill bit slips.

Countermeasures for collapsing drill bit ligaments

1. Choose a drill with a larger back taper.

2. Check the range of spindle drill runout (<0.02mm).

3. Use a pre-centered drill for the top hole.

4. Use a more rigid drill bit with a necking sleeve or a hydraulic chuck with a heat shrink kit.

Causes of drill bit accumulation of chipping tumors

1. Caused by chemical reaction between cutting material and workpiece material (mild steel with high carbon content).

Countermeasures for drill bit chipping tumor accumulation

1. Improve the lubricant and increase the oil or additive content.

2. Increase the cutting speed and reduce the feed rate to reduce the contact time.

3. If drilling aluminum, use a drill with polished and uncoated surface.

Causes of drill bit broken tool

1. The spiral groove of the drill bit is blocked by cutting and the cutting is not discharged in time.

2. When drilling a hole quickly, the feed is not reduced or the motor is changed to manual feed.

3. When drilling soft metals such as brass, the back angle of the drill bit is too large and the front angle is not resharpened, so that the drill bit spins in automatically.

4. The drill edge is resharpened too sharply, resulting in chipping, and the tool is not retired quickly.

Countermeasures for broken drills

1. Shorten the cycle of tool replacement.

2. Improve the installation and fixing, such as increasing the support area and the clamping force.

3. Check the spindle bearing and sliding groove.

4.Use high precision toolholder, such as hydraulic toolholder.

5. Use tougher materials.

Selection of drill bit

Judging from experience, generally speaking the white ones are usually fully ground HSS drill bits and should be of the best quality. The gold ones are titanium nitride plated, which are generally either the best or poorer fooling around. The black ones also vary in quality, and some are made of very poor carbon tool steel, which is easy to anneal, and at the same time easy to rust so they should be blackened. Generally buy drill bits can look at the logo on the shank of the drill and the diameter tolerance mark, clear logo, laser or electro-etching quality is not too bad. If the word is pressed by the word mold, if the edge of the word bulges up, the drill bit is of poor quality, because the bulging word profile will lead to the drill bit clamping accuracy can not meet the requirements, and the word edge is clear, very good and the cylindrical surface of the drill bit shank junction of the good quality. Also look at the cutting edge at the tip of the drill bit. The edge of a fully ground drill bit is well opened and the spiral surface meets the requirements, while the poor quality is poor at the back corner surface.

The difference between drill bits

There are 3 processes to produce drill bits, black is rolled, the worst. The white one is edge clearing and grinding. Because, unlike rolling, it does not produce high temperature oxidation, the steel grain organization is not destroyed and is used to drill slightly harder workpieces. The yellowish-brown drill bit is called cobalt drill in the industry, which is the unspoken rule of the drill industry. M35 (Co 5%) is another kind of gold, this kind of drill is called titanium plated drill, which is divided into decorative plating and industrial plating. Decorative plating is not useful at all, it's just nice and golden. Industrial plating is very good, the hardness can reach HRC78, than the cobalt drill hardness is higher (HRC54).

VIDO is a professional tool manufacturer, producing a wide range of tools, including drills, chainsaws, mold grinders, etc.. Many of our products are exported overseas and have been recognized by everyone. If you are interested in VIDO's products, please feel free to contact our company.