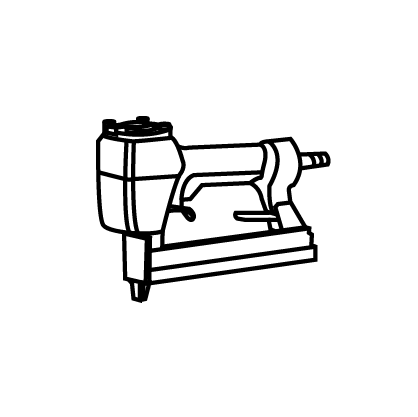

Automatic spray guns are used in a wide range of applications, mainly in the automotive industry, shipping industry, equipment manufacturing. So for the automatic spray gun think you do not know very well. Then follow me down to see it.

Automatic spray gun purchase considerations.

1. According to the size and quality of the gun itselfFrom the consideration of reducing the operator's labor intensity, I hope the gun body light and small for good, but the amount of paint sprayed and air volume also decreases with the increase in spraying time, operating efficiency decreases, not suitable for a large number of painting occasions. If you use a large spray gun to spray small parts or tubular objects, the paint loss is large. Large planar coated objects can use large spray gun; small spray gun is suitable for the coated objects with very different convexity.

2. The amount of paint and paint supply method

Small amount of paint, color change frequently, choose gravity spray gun, but not for face up spraying; paint amount and color change more, especially when spraying the side, choose the capacity of 1L or less with a canister suction gun more convenient. If the amount of paint is large, the color is almost unchanged continuous operation, you can choose the pressure-fed spray gun, with paint booster tank for paint. In case of larger paint dosage, the paint can be continuously sprayed without terminating the operation by using a pump and paint circulation pipe to press feed the paint. Spraying with quick-change joints, easy to clean and color change, pressure-fed spray gun without paint cups or cans, spraying up and down, flexible and convenient.

3. Nozzle caliber

Industrialized mass production, the unit time through the coating area, the large amount of paint, the nozzle diameter of the selected gun to be large; when spraying high film thickness requirements or spraying primer and the quality of the paint film appearance requirements are not high, to choose a larger caliber gun. In addition, when the elected paint construction viscosity is high, choose a larger caliber gun, and the use of low-viscosity paint or pressure-fed supply of paint, to choose a smaller caliber gun. When spraying topcoat, paint atomization requirements are high, but also to choose a smaller caliber gun.

Automatic spray gun maintenance.

1. After each work, the gun should be carefully flushed clean, especially the nozzle and air cap of each hole.

2. every day before work for a thorough cleaning (disassembly of the nozzle, wind cap, gun needle), cleaning the air hole, the use of hard steel wire stabbing (eg: big head pin, paper clip, etc.) is strictly prohibited, so as to avoid deformation of the air hole, a small deformation will affect the atomization effect.

3. gun cleaning, the application of special gun lubricant lubrication of all removable friction parts, take care not to apply in the front of the gun needle.

4. When disassembling and installing the nozzle three-piece parts, should strictly follow the procedures: gun cap, gun needle, gun nozzle. If you violate the operation procedure, it is easy to lead to nozzle expansion and cracking and other phenomena.

5. Nozzle three pieces set with other nozzle set of the same type shall not be arbitrarily interchangeable, nor shall a part of the replacement alone.

6. When adjusting the wind cap, the font on the wind cap shall not be inverted. Otherwise, the uniformity of the spray width may be affected.

7. It is recommended that an air pressure gauge be installed at the end of the gun to regulate and control the spraying air pressure. The stability of air pressure can ensure uniform spraying color and paint film thickness.

8. It is strictly forbidden to immerse the entire gun in cleaning solvent to avoid solvent entering the air duct of the gun and causing damage to the gun.

9. spraying air pressure is too low will lead to serious orange peel pattern of the paint film, poor atomization; air pressure is too high will produce a coating "dry spray" phenomenon, the film gloss or paint adhesion is reduced, but also produce uneven atomization phenomenon (the paint at both ends of the spray width than the middle part, which is often referred to as the "starting bar ", "cloud" phenomenon).

10. Before each work or after cleaning should check the tightening of the components. Especially the fixed bolt of the spraying air pressure adjustment knob.

VIDO is a professional tool manufacturer, producing a wide range of professional tools, including automatic spray guns, chainsaws, etc.. A wide variety of products, exported overseas, and won the unanimous praise of everyone. If you are interested in automatic guns or other tools, you can contact our company.