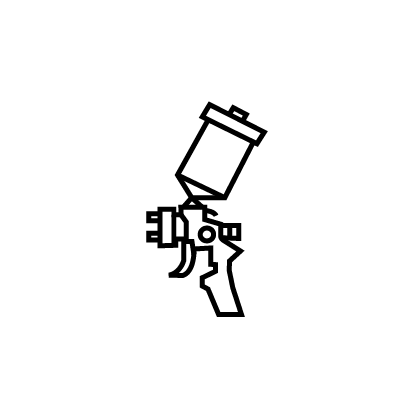

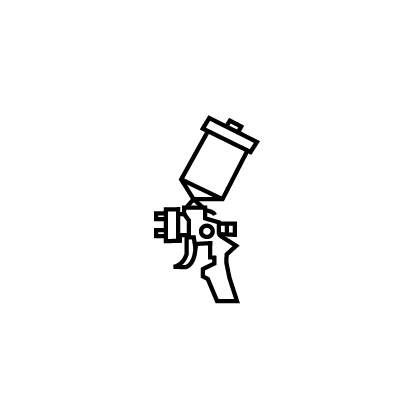

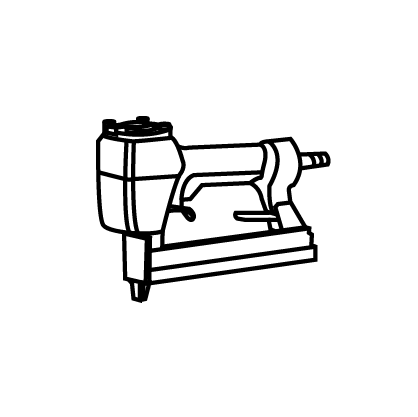

Percussion drill refers to an electric tool mainly used for rotary cutting and an impact mechanism that relies on the thrust of the operator to produce impact force. It is used to drill holes in materials such as bricks, blocks and lightweight walls.

Application of impact drill:

Impact drills can be used for natural stone or concrete. They are universal, because they can be used in either "single drill" mode or "percussion drill" mode, so for professionals and DIYers, it is a basic power tool worth choosing. The electric hammer works by rotating and beating. A single beating force is very high, and has a beating frequency of 1000 to 3000 per minute, which can generate a significant force. Compared with percussion drills, electric hammers require minimal pressure to drill into hard materials, such as stones and concrete; especially relatively hard concrete. The electric drill only has a rotating method, which is particularly suitable for drilling holes in materials that require a small amount of force, such as cork, metal, brick, and ceramic tiles. The impact drill relies on rotation and impact to work. A single impact is very slight, but the impact frequency of more than 40,000 per minute can produce a continuous force.

Impact structure of impact drill:

The impact mechanism of the impact drill has two types: dog tooth type and ball type. The ball impact drill is composed of a movable plate, a fixed plate, and a steel ball. The movable plate is connected to the main shaft by threads and has 12 steel balls; the fixed plate is fixed on the casing with pins and has 4 steel balls. Under the action of thrust, the 12 steel balls roll along the 4 steel balls. The cemented carbide drill bit produces a rotary impact motion, which can drill holes in brittle materials such as bricks, blocks, and concrete. Take off the overhead nails, make the fixed plate and follow-up plate rotate together without impact, and can be used as an ordinary electric drill.

1. Power switch.

2. Reverse order limit switch.

3. Drill chuck.

4. Power supply voltage regulation and clutch control twist.

5. Change the voltage to realize a two-stage transmission mechanism.

6. Auxiliary handle, positioning ring, housing set screw, etc.

7. Forward and reverse steering control mechanism.

8. The gear set inside the machine.

9. The housing is insulated to hold the handle.

How to use impact drill:

1. Before operation, you must check whether the power supply is consistent with the conventional rated 220V voltage on the power tool, so as not to connect it to the 380V power supply by mistake.

2. Before using the impact drill, please carefully check the body insulation protection, auxiliary handle and depth gauge adjustment, etc., whether the machine has any loose screws.

3. The percussion drill must be fitted with an alloy steel percussion drill bit or a general-purpose drill bit within the allowable range between φ6-25MM according to the material requirements. It is strictly forbidden to use drill bits beyond the scope.

4. The wire of the impact drill should be well protected. It is strictly forbidden to drag the wire all over the floor to prevent it from being damaged or cut, and it is not allowed to drag the wire into the oil and water to prevent the oil and water from corroding the wire.

5. The power socket of the impact drill must be equipped with a leakage switch device, and check whether the power cord is damaged. If the impact drill is found to have leakage, abnormal vibration, high heat or abnormal noise during use, stop work immediately and find an electrician to check and repair in time .

6. When replacing the drill bit of the impact drill, use a special wrench and drill bit to lock the key to prevent the use of non-special tools to hit the impact drill.

7. When using an electric impact drill, remember not to use excessive force or skewed operation. Make sure to install a suitable drill bit and adjust the depth gauge of the impact electric drill beforehand. When operating in a vertical and balanced manner, apply force slowly and evenly. Do not use oversized drills forcibly.

8. Proficiency in mastering and operating the forward and reverse steering control mechanism, tightening screws and drilling and tapping functions.

VIDO is a manufacturer of professional tools, including percussion drills, electric drills, etc. The products are exported overseas and have won unanimous praise from everyone. If you are interested in impact drills or other products, you can contact our company.